Rejection sheet. How to fill out a rejection log correctly!!! To pass the screening, you must

The concept of rejection is the testing of manufactured products by production and public catering establishments before sale. A qualitative assessment of products is carried out by a locally appointed commission. All conclusions and comments are entered into the finished product rejection log; a sample of the filling can be viewed here.

Based on the Resolution of the State Chief Physician of the Sanitary Service of the Russian Federation No. 20, No. 4303, as well as the provisions of SanPiN, mandatory control of finished products is required before they are sold to consumers. This is especially strict for meals in preschool and school institutions.

The results of product samples are entered into a rejection journal, which consists of pages with columns where the following is written:

- Exact cooking (release) time.

- Name of product (dish).

- Date of implementation of the defect control.

- Conclusions of organoleptic examination and sufficient readiness of the product.

- Implementation and use decision.

- Visas of commission members.

- Addition (in the form of a note).

The reject log is prepared by filling out the appropriate columns, numbering, visa and the seal of the enterprise. The document must be laced and stored with the production manager. You can view a sample of filling out a reject log for finished products here.

The production rejection log confirms the enterprise’s intention to carry out quality control. Instead of a specialized commission in the field of catering, the senior cook (pastry chef) is allowed to carry out screening and fill out a magazine of the established form. The employer grants this right to the kitchen worker in accordance with qualifications, professional qualities and the corresponding rank.

The cook personally tastes the dishes and records the data on organoleptic indicators in a journal, certifying them with a personal signature.

The quality of dishes does not always depend on the professionalism of the chefs. The purchased products, their freshness, compliance with shelf life, recipes, and compliance with technology standards are of great importance.

Important! When inspecting catering establishments, Rospotrebnadzor representatives always first ask for a rejection log.

Characteristics of the rejection process

Products are checked by taking a sample or laboratory analysis. So, for example, before serving a dish to the consumer, 15-20 minutes before the food is served, a sample must be taken. Organoleptic indicators are entered into a rejection register and recorded in it, indicating all the necessary requirements.

The organoleptic requirements of products include the relationship between appearance and taste. During the grading process, technology and costing are also studied.

The product is weighed, attention is paid to consistency, appearance (external and cut), smell, taste, transparency. This applies not only to dishes from the catering department, but also to products of all types, including semi-finished products. When checking, the ratings are given: 5, 4, 3 or 2. An unsatisfactory rating prohibits acceptance of the product, it is removed from production and sales by the rejection commission.

When conducting an inspection, there may be a need for laboratory tests, which members of the commission notify by making an entry in the sampling report. Products for laboratory testing are packaged in tightly closed containers, wrapped in paper, tied with twine and sealed.

A negative test response is grounds for removing products from sale. This fact must be recorded in the reject log.

Control over the quality of food preparation, the release of finished products and the release of semi-finished products can be departmental, administrative and personal. The first includes a special commission created at the enterprise. Personal inspection is carried out directly by the employer himself or by manufacturers directly on site. Administrative control is carried out by the production manager. During the working day, quality control is carried out by foremen.

The rejection commission itself includes (Letter of the Public Catering Administration No. 7-3/8-867) in small enterprises: the director and production manager, a senior cook in the team, a health worker. In large industries, the list of persons listed also includes: a process engineer, a laboratory worker, a highly qualified cook or pastry chef, a sanitation station worker (or a member of the production sanitation post).

Important! The composition and number of members of the rejection commission is approved by order of the management, including the people's control group, as well as trade unions.

Legal nuances

Despite the fact that there are no direct regulatory instructions on working with rejection logs in the Rules SP 2.3.6.1079-01, clause 15.1 of these provisions directly states that it is necessary to maintain daily documentation on the preparation and release of finished products and control the quality of frying fats.

These requirements apply to ready-made batches of food, drinks, confectionery, cheese, sausage, dairy and other types of products, as well as semi-finished products.

Clause 1 of the joint venture recommends in public catering sampling and evaluation as each portion of products is prepared, produced according to demand and sales (clauses 8.3, 9.1). Recording in the journal must be carried out in accordance with all the rules and signed by authorized persons - the manufacturer and the inspector (Letter of the Ministry of Trade No. 0848).

The form of the rejection log is provided for by the standards of NP SRO APSPOZ, as well as SanPiN:

- 4.1.3049 – 13 (Appendix 8, table 1);

- 4.5.2409 – 08 (Appendix 10, form 2).

The algorithm of action of the Rospotrebnadzor inspection service when conducting rejection commissions is based on Appendix 15 of Rospotrebnadzor Order No. 220.

If during the inspection process a product of inadequate quality is revealed, it is brought to the required condition. If this is not possible, then persons who damaged the product and violated manufacturing rules will compensate for material damage from their personal income.

Important! Ensuring the quality of manufactured products must be carried out in accordance with strict adherence to technological disciplines and the manufacturing process, technical documents.

Conclusion

A waste log is an important element of monitoring the products a person consumes. It is necessary to control the process of cooking and semi-finished products in order to protect your health from unnecessary problems.

AGREED:

Head of Trade and Nutrition Department

and consumer services

AGREED:

Head to the health department

on removing defects of finished products in school canteens for parents and members of school rejection commissions

1. Quality control and safety of finished products in school canteens

Quality control of finished products begins with checking the availability of technical (technological) documentation (collection of recipes, technological maps) for each type of dish. The production of ready-made dishes is carried out in accordance with technological maps, which must reflect the recipe and technology of the prepared dishes and culinary products. The description of the technological process for preparing dishes, including newly developed dishes, must contain a recipe and technology that ensures the safety of the prepared dishes and their nutritional value.

The process of preparing a dish must be organized in full accordance with the technological documentation.

2. Terms of sale of finished products

Ready-to-eat food is provided to children only after a sample has been taken by members of the screening commission. The sample is taken minutes before serving the finished food.

The rejection log gives an assessment of each dish by the commission members and a note on permission to issue. Ready-made first and second courses can be kept on a steam table or hot plate for no more than 2 hours from the moment of production, or in isothermal containers (thermoses) - for a time that ensures that the temperature is not lower than the serving temperature, but no more than 2 hours. Heating ready-made hot dishes that have cooled below the serving temperature is not permitted. If the cooking technology is violated and in case of unpreparedness, the dish is not allowed to be served until the identified culinary deficiencies are eliminated.

The quality of finished dishes is assessed by the organoleptic method (appearance, color, smell, taste, consistency). Depending on these indicators, products are rated - “excellent”, “good”, “satisfactory”, “unsatisfactory” (defective).

The rating “excellent” is given to such dishes and culinary products that match the taste and color. Smell, appearance and consistency, approved recipe.

The “good” rating is given to dishes and culinary products that have one minor defect (under-salted, not brought to the desired color, etc.).

A “satisfactory” rating is given to dishes and culinary products that have deviations from culinary requirements, but are suitable for sale without processing.

A rating of “unsatisfactory” (defective) is given to products that have the following shortcomings: foreign, unusual taste and smell, sharply over-salted, undercooked, burnt, lost their shape, having an unusual consistency or other signs of non-compliance with the recipe of the dish.

For reference. When served, hot dishes (soups, sauces, drinks) must have a temperature of no lower than 75°C, main courses and side dishes - no lower than 65°C, cold soups, drinks - no higher than 14°C.

Ready-to-eat dishes made from raw vegetables can be stored in the refrigerator at a temperature of 4±2°C for no more than 30 minutes.

Salads are prepared and dressed immediately before distribution. Undressed salads can be stored for no more than 3 hours at a temperature of plus 4 + 2 C. Storage of dressed salads is not allowed.

The use of sour cream and mayonnaise for salad dressing is not allowed. Vinegar in food recipes should be replaced with citric acid.

The results of the rejection are reflected in the “Journal of Rejection of Finished Culinary Products”.

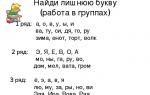

Date, hour of preparation of the dish | Rejection time | Name of dish, culinary product | Results of organolyptic evaluation and degree of readiness of a dish or culinary product | Permission to sell a dish or culinary product | Signatures of members of the marriage commission | Note * |

Perspective menu day 1. |

||||||

Cheese Fish cutlet Boiled horns Tea with sugar Bread | excellent quality qualitatively | Issuance permitted |

Tomato salad and fresh cabbage Poultry ragout Fresh apple compote |

good (not too salty) satisfactory (boiled apples, cloudy color) | Issuance permitted |

Note:

*Indicates facts of prohibition on the sale of finished products

The screening commission consists of 5 people: the chairman of the commission is a representative of the school administration (school director, head teacher), the members are the head. production (cook-foreman) of the school canteen, health worker responsible for nutrition, members of the parent and student committee. The sale of ready-made dishes and products without rejection is strictly prohibited.

Methodology for organoleptic evaluation of food

Organoleptic evaluation begins with external examination of food samples. It is better to carry out the inspection in daylight. Inspection determines the appearance of the food and its color.

Then the smell of the food is determined. This indicator is especially important, because with the help of smell it is possible to establish subtle changes in the smell of food products, especially in meat and fish, associated with the initial phenomena of spoilage, when these changes cannot be determined by other means. The smell should be determined at the temperature at which the food is consumed. The smell is best detected by holding your breath.

The consistency of products is determined using the sense of touch.

The fingertips, as well as the tongue and palate, have the greatest sensitivity.

and teeth. In the process of chewing food, its hardness, juiciness,

tenderness. Tactile sensations, especially of the tongue, are caused by

perception of oiliness, stickiness, mealiness, stickiness,

coarse grain, friability, etc.

The taste of food, like the smell, should be established at its characteristic temperature. Basic taste sensations: sour, sweet, bitter, salty. The tip of the tongue is most sensitive to sweet and salty, the root area to bitter, and the edge to sour.

4 Organoleptic evaluation of the first dishes

For organoleptic examination, the first dish is thoroughly mixed in a cauldron and taken in a small amount onto a plate. The appearance and color of the dish are noted, by which one can judge whether the technology of its preparation has been followed. For example, the brownish-brown color of borscht may be the result of improperly stewing beets. You should pay attention to the quality of processing of raw materials: thorough cleaning of vegetables, the presence of foreign impurities and contamination.

When assessing the appearance of soups and borscht, check the shape of the cutting of vegetables and other components, their preservation during the cooking process (there should be no bruised, out of shape or overcooked vegetables and other products). It is advisable to compare the set of roots and vegetables seen when viewing the dense part of the first course with the recipe according to the layout.

During organoleptic evaluation, attention is paid to the transparency of soups and broths, especially those made from meat and fish.

Poor quality meat and fish produce cloudy broths; the drops of fat are finely dispersed and do not form greasy amber films on the surface.

When checking pureed soups, pour the sample in a thin stream from a spoon into a plate, noting the thickness, uniformity of consistency, and the presence of unpureed particles. The puree soup should be homogeneous throughout the entire mass, without peeling off the liquid on its surface.

When determining taste and smell, it is noted whether the dish has its inherent taste, whether there is any foreign taste and smell, the presence of bitterness, acidity unusual for a freshly prepared dish, under-salting, or over-salting. For dressing and clear soups, try the liquid part first, paying attention to the aroma and taste. If the first dish is seasoned with sour cream, then first try it without sour cream.

In a child care facility, dishes with the taste of raw and burnt flour, undercooked or overcooked foods, lumps of cooked flour, sharp acidity, oversalting, etc. should not be allowed.

Organoleptic evaluation of second courses

In dishes served with a side dish and sauce, all components are assessed separately. The rating of sauce dishes (goulash, stew) is given overall.

When externally examining dishes, pay attention to the nature of cutting pieces of meat (across or along the grain), uniformity of portioning, surface color, the presence of a fried crust on both sides of the product, and the thickness of the breading layer. In meat and fish products, the color is determined both on the surface and on the cut, which makes it possible to identify violations in the cooking technology. Thus, the weathered surface of boiled meat products indicates long-term storage without broth; pinkish

The red color on the cutlet's cut indicates that the cutlet is not cooked enough or that the cutlet's shelf life has expired.

An important indicator that gives an idea of the degree of readiness of a dish and, in part, of compliance with the recipe when preparing it, is the consistency of the dish (for example, the spreadable consistency of minced meat products indicates the addition of an excess amount of bread to the minced meat). The degree of readiness and consistency of meat products, poultry and fish are determined by piercing them with a chef's needle or wooden pin, which should easily penetrate the thickness of the finished product.

When determining the taste and smell of dishes, pay attention to the presence of specific odors. This is especially important for fish, which easily acquire foreign odors from the environment. Boiled fish should have a taste characteristic of its given type with a well-defined taste of vegetables and spices, and fried fish should have a pleasant, slightly noticeable taste of fresh fat in which it was fried. It should be soft, juicy, not crumbly, and retain its cut shape.

Poultry meat should be soft, juicy and easily separated from the bones.

If there are cereal, flour or vegetable side dishes, their consistency is also checked. In crumbly porridges, well-swollen grains should be separated from each other. Distributing the porridge in a thin layer on a plate, check for the presence of unhulled grains, foreign impurities, and lumps in it. When assessing the consistency of porridge, it is compared with the one planned according to the menu layout, which makes it possible to identify shortcomings.

Pasta, if cooked correctly, should be soft and easily separated from each other, without sticking, hanging from the edge of a fork or spoon. Cereal balls and cutlets should retain their shape after frying.

When evaluating vegetable side dishes, pay attention to the quality of peeling of vegetables and potatoes, the consistency of the dishes, their appearance, and color. So, if mashed potatoes are liquefied and have a bluish tint, you should inquire about the quality of the original potatoes, the percentage of waste, filling and yield, and pay attention to the presence of milk and fat in the recipe. If there is a suspicion that the recipe does not comply, the dish is sent to the laboratory for analysis.

The consistency of sauces is determined by pouring them in a thin stream from a spoon into a plate. If the sauce contains sautéed roots and onions, they are separated and the composition, cut shape, and consistency are checked. Be sure to pay attention to the color of the sauce. If it includes tomato and fat or sour cream, the sauce should be a pleasant amber color. A poorly prepared sauce, with particles of burnt onions, has a gray color and a bitter, unpleasant taste. A dish topped with such a sauce does not arouse the child’s appetite and reduces the taste of the food and, consequently, its absorption.

A daily sample of the finished product should be left daily. The collection and storage of daily samples is carried out by a medical worker; in his absence at school, the daily sample is taken by the head. production or

responsible for food. The sample should be taken in a labeled, sterile or boiled glass container with a tightly closing glass or metal lid (the side dish is taken in a separate container). Samples of all finished culinary products are left, except for bread, flour products, tea, and fruit. Portioned dishes are selected in full; salads, first and third courses, side dishes - at least 100 grams. The selected samples are stored for at least 48 hours (not counting weekends and holidays) in a special refrigerator or in a specially designated place in the refrigerator at a temperature of +2 - +6°C.

The concept of rejection is the testing of manufactured products by production and public catering establishments before sale. A qualitative assessment of products is carried out by a locally appointed commission. All conclusions and comments are entered into the finished product rejection log, which can be viewed here.

Based on the Resolution of the State Chief Physician of the Sanitary Service of the Russian Federation No. 20, No. 4303, as well as the provisions of SanPiN, mandatory control of finished products is required before they are sold to consumers. This is especially strict for meals in preschool and school institutions.

The results of product samples are entered into a rejection journal, which consists of pages with columns where the following is written:

- Exact cooking (release) time.

- Name of product (dish).

- Date of implementation of the defect control.

- Conclusions of organoleptic examination and sufficient readiness of the product.

- Implementation and use decision.

- Visas of commission members.

- Addition (in the form of a note).

The reject log is prepared by filling out the appropriate columns, numbering, visa and the seal of the enterprise. The document must be laced and stored with the production manager. You can view a sample of filling out a reject log for finished products here.

The production rejection log confirms the enterprise’s intention to carry out quality control. Instead of a specialized commission in the field of catering, the senior cook (pastry chef) is allowed to carry out screening and fill out a magazine of the established form. The employer grants this right to the kitchen worker in accordance with qualifications, professional qualities and the corresponding rank.

The cook personally tastes the dishes and records the data on organoleptic indicators in a journal, certifying them with a personal signature.

The quality of dishes does not always depend on the professionalism of the chefs. The purchased products, their freshness, compliance with shelf life, recipes, and compliance with technology standards are of great importance.

Important! When inspecting catering establishments, Rospotrebnadzor representatives always first ask for a rejection log.

Characteristics of the rejection process

Products are checked by taking a sample or laboratory analysis. So, for example, before serving a dish to the consumer, 15-20 minutes before the food is served, a sample must be taken. Organoleptic indicators are entered into a rejection register and recorded in it, indicating all the necessary requirements.

The organoleptic requirements of products include the relationship between appearance and taste. During the grading process, technology and costing are also studied.

The product is weighed, attention is paid to consistency, appearance (external and cut), smell, taste, transparency. This applies not only to dishes from the catering department, but also to products of all types, including semi-finished products. When checking, the ratings are given: 5, 4, 3 or 2. An unsatisfactory rating prohibits acceptance of the product, it is removed from production and sales by the rejection commission.

When conducting an inspection, there may be a need for laboratory tests, which members of the commission notify by making an entry in the sampling report. Products for laboratory testing are packaged in tightly closed containers, wrapped in paper, tied with twine and sealed.

A negative test response is grounds for removing products from sale. This fact must be recorded in the reject log.

Control over the quality of food preparation, the release of finished products and the release of semi-finished products can be departmental, administrative and personal. The first includes a special commission created at the enterprise. Personal inspection is carried out directly by the employer himself or by manufacturers directly on site. Administrative control is carried out by the production manager. During the working day, quality control is carried out by foremen.

The rejection commission itself includes (Letter of the Public Catering Administration No. 7-3/8-867) in small enterprises: the director and production manager, a senior cook in the team, a health worker. In large industries, the list of persons listed also includes: a process engineer, a laboratory worker, a highly qualified cook or pastry chef, a sanitation station worker (or a member of the production sanitation post).

Important! The composition and number of members of the rejection commission is approved by order of the management, including the people's control group, as well as trade unions.

Legal nuances

Despite the fact that there are no direct regulatory instructions on working with rejection logs in the Rules SP 2.3.6.1079-01, clause 15.1 of these provisions directly states that it is necessary to maintain daily documentation on the preparation and release of finished products and control the quality of frying fats.

These requirements apply to ready-made batches of food, drinks, confectionery, cheese, sausage, dairy and other types of products, as well as semi-finished products.

Clause 1 of the joint venture recommends in public catering sampling and evaluation as each portion of products is prepared, produced according to demand and sales (clauses 8.3, 9.1). Recording in the journal must be carried out in accordance with all the rules and signed by authorized persons - the manufacturer and the inspector (Letter of the Ministry of Trade No. 0848).

The form of the rejection log is provided for by the standards of NP SRO APSPOZ, as well as SanPiN:

- 4.1.3049 – 13 (Appendix 8, table 1);

- 4.5.2409 – 08 (Appendix 10, form 2).

The algorithm of action of the Rospotrebnadzor inspection service when conducting rejection commissions is based on Appendix 15 of Rospotrebnadzor Order No. 220.

If during the inspection process a product of inadequate quality is revealed, it is brought to the required condition. If this is not possible, then persons who damaged the product and violated manufacturing rules will compensate for material damage from their personal income.

Important! Ensuring the quality of manufactured products must be carried out in accordance with strict adherence to technological disciplines and the manufacturing process, technical documents.

Conclusion

A waste log is an important element of monitoring the products a person consumes. It is necessary to control the process of cooking and semi-finished products in order to protect your health from unnecessary problems.

TERMS

Grading is the process of deciding on the conformity of the appearance and taste of products by taking a sample.

Product write-off is the disposal of products if they are found to be non-compliant with the requirements. For each fact of write-off of products, an act is drawn up ( Annex 1), in which the signatures of the head of the establishment (production) and the foreman or head of the workshop in which the write-off occurs are mandatory. The employee who committed the defect at work is familiarized with the act against signature.

The rejection commission is an authorized group of employees (production director, production manager, culinary market director).

A culling journal is a journal in which all tested dishes are noted and each of them is given a rating.

Inadequate condition – products of inadequate quality and/or appearance.

DESCRIPTION OF THE PRODUCTION PROCESS

| Action | Performer/responsible | Note |

| Purchase and storage of raw materials | ||

| Organoleptic testing of purchased raw materials (meat, mushrooms - on commission). | Head warehouse (meat, mushrooms - accepted by warehouse manager, merchandiser, production director) | In case of acceptance of low-quality raw materials, financial responsibility falls entirely on the warehouse manager (or on the members of the commission accepting the raw materials). |

| Organoleptic testing of raw materials sent to the workshop. | Head warehouse | In case of damage to raw materials during storage, financial responsibility falls entirely on the warehouse manager. |

|

Production stage(responsible - deputy production director) |

||

| Acceptance of raw materials is carried out according to quality and quantity. | Foreman or shop manager | After receiving raw materials from the warehouse, financial responsibility falls entirely on the storekeeper and production manager; they are financially responsible for the quality and use of these raw materials. Meat, chickens, mushrooms, vegetables, fruits are accepted on commission: storekeeper and production manager. The production manager accepts the quality and is responsible, along with the storekeeper, for the quality of raw materials. He has every right not to accept low-quality raw materials if he does not participate in the acceptance of the goods. The warehouseman returns the goods to the supplier or this amount is deducted from the warehouseman's salary. |

| rejecting finished products. Taste, color, smell, consistency | Products of inadequate quality are subject to write-off. If this happened through the fault of the employee, then the employee on the same day pays the amount of the damaged products at retail prices. If an employee is unable to pay this amount, then this amount is written out to him by the accounting department in the form of an advance and immediately withheld. | |

| rejecting finished products. | Foreman or shop manager, deputy. production director | Before starting the production of a batch of products, it is necessary to check the quality, for this you should prepare a sample and taste it. The chef, production manager, and foreman taste it. Only after this is it allowed to produce the product in a given volume and send it for sale, this also applies to /f. After permission for production is given, the above persons bear full moral and financial responsibility for the quality of this batch of products. . After the rejection, a note is made in the rejection log. Products with inadequate taste quality must be brought to taste. If it is impossible to bring it to taste, then the product is written off. If this happens, then the products are purchased by the employee who produced the products and by the persons who allowed this to happen. On the same day, the amount of damaged products at retail prices is withheld. If an employee is unable to pay this amount, then this amount is written out to him by the accounting department in the form of an advance and immediately withheld. |

| When producing chopped semi-finished products and minced meat, it is necessary to prepare a sample and taste it on commission before making a batch of the semi-finished product. | Foreman or shop manager, deputy. production director | |

| Repeated rejection of finished products on expedition | Forwarder | Products are accepted according to organoleptic indicators and quantity. If a defect is discovered, the foreman and production manager are invited. An act is drawn up and a decision is made on return and modification or write-off at the expense of the culprit. After accepting the products for the expedition, the forwarder bears financial responsibility for storage. |

| Delivery stage(responsible – driver) | ||

| Delivery driver | Products with improper appearance will not be shipped. Financial responsibility for low-quality products falls entirely on the forwarder. If an employee is unable to pay this amount, then this amount is written out to him by the accounting department in the form of an advance and immediately withheld. | |

| Organoleptic rejection of finished products | Financially responsible person at the point of sale, barmaid | Products with improper appearance will not be accepted. Side dishes, soups, drinks, main courses, and baked goods are tasted on site. In case of defective or damaged products, they are returned to the expedition. The production manager is invited and a report is drawn up. The culprit pays. |

Notes: Local adjustments are made.

1. If a defect is detected after the sale of products, the manager draws up a product return certificate (Appendix 2), the causes of substandard conditions are identified and established. The money paid by the buyer for defective products is returned to the buyer. A copy is made of the act and sent to production through the driver.

2. When sending products to a chain of stores, the products are written off independently. The act is signed by the store director, the sales floor administrator, the salesperson in the “Donut” department and the security officer. The original act is transferred to the Pyshka accounting department through the driver, and a copy remains with the store director. In stores, products are allowed to be written off in pre-agreed volumes (as a rule, this is a percentage of products sold). If it is the fault of the manager, the manager is notified within 1 hour.

3. Returning products from the culinary market at the end of the working day:

Meat products are returned to the meat shop.

Salads are returned to the cold shop.

Goth. The dishes are returned to the hot shop.

All baked goods are moved to storage in a refrigerated cabinet during the expedition.

The confectionery products remain in the store's display cases, and in the morning the head of the confectionery shop comes by and evaluates them.

The production manager draws up a distribution menu taking into account these leftovers.

Annex 1.

Workshop ACT

write-off of products

1. Today ___. ____. 200__ year at ___ h. ___ min. us:

Position Full name

________________________________ _________________

Position Full name

________________________________ _________________

Position Full name

Products written off (due to defects/damage/defects) in the following range:

| № | Name of product | Number of products | Retail price per unit | Full name and position of the responsible person | Place of detection of defect |

| 1 | |||||

| 2 | |||||

| 3 | |||||

| 4 | |||||

| 5 |

Job title Full name

for causing damage in the amount of ______ (_____________________________

Suma in cuirsive

___________________________) rub. ____kop. and not pay for __ working hours.

3. Defective products were handed over to the guilty employee and disposed of (cross out what is unnecessary).

Signatures:

Signature Full name

____________ /________________

Signature Full name

____________ /________________

Signature Full name

Signature Full name

__________________ Appendix 2Name of company

__________________

Structural subdivision

product return

To be completed by the head of the point of sale or his deputy

1. Today ___. ____. 200__ year at ___ h. ___ min. client ___________________

Full name

__________________________________________ ______________________

Home addresscontact number

Products purchased ___/___/200__ in ___ hours were returned in the following assortment:

2. Based on the “Internal Regulations”

the client _____________________ was returned an amount of ______ rubles. ___kop.

Head of sales point ________________ /____________________ /_______________

Position Signature Full name

Security officer ____________ /_______________ Buyer ___________

3. Based on the “Regulations on product defects and the process of writing off defects”

hold with __________________________________ ____________________

Job title Full name

for causing material damage in the amount of

_________ (________________________________________________) rub. ____ kop.

Suma in cuirsive

Signatures: Deputy production director: ____________ / ________________

Signature Full name

I have read the act: ____________ /________________