LEAN. Lean. Practical guide. Lean Manufacturing: A Practical Guide to Exploring the Toyota Production System from a Manufacturing Organization Perspective

Lean Manufacturing: How to Eliminate Waste and Make Your Company Prosper

- Lean manufacturing is, without exaggeration, the main thing worth learning from the Japanese in the field of management.

- Every manager, regardless of industry, should know this method, because its basis is to combat losses.

- This book became an international bestseller and went through many reprints.

The book is written in detail, clearly and contains not only a description of the theory, but also many examples from the experience of leading companies in the USA, Germany and Japan.

Study of the Toyota production system from the point of view of production organization

If a company is just beginning to explore the possibilities of applying the methods and tools of the Toyota Production System, then this book should be read by managers.

If a company has decided to implement lean manufacturing tools in its company or is already on this path, then every employee should read and use this book in daily practice.

This book will be useful to everyone involved in production processes. And not only at the factory, but also in the office.

The Toyota Way: 14 management principles for the world's leading company

Why the book is worth reading

- Toyota's example inspires and pushes us on the path to personal achievement;

- The publication is based on 20 years of observation and study of the company's philosophy, thus incorporating the “improved” and most effective formula for success;

- Debunking myths about the impossibility of using foreign experience on the Russian market;

- Secrets of long-term success, based not on newfangled management trends, but on timeless management classics.

Who is this book for?

For managers and entrepreneurs, as well as students and teachers of economic universities.

Why the book is worth reading

- A timeless classic of efficient production, relevant at all times.

- Methods to reduce labor costs are not a myth, but a reality;

- Free time at work: how it is better to do nothing than to do something unnecessary;

- What are the consequences of the absence of a production leveling system?

- Synthesis of Japanese and American management styles - how effective is it?

Who is this book for?

Designed for managers seeking to reduce production losses and improve their company's production system; for managers of all levels and students whose specialty lies in the field of production and services.

Learn to see business processes: Practice of creating value stream maps

To improve processes, first of all, it is necessary to ensure their visualization and transparency, that is, to clearly see and understand how the process works, where added value is created, where losses occur. Value stream maps allow you to describe processes of any kind, both production and service. This book is the first publication in Russia that describes in detail the methodology for constructing value stream maps - one of the most important tools of lean manufacturing. The proposed methodology was developed by Michael Rother and John Shook based on their personal experience with Toyota. The book is aimed at practicing managers, as well as specialists in any field of activity who are interested in improving the efficiency of business processes. It can be used as a teaching aid for students of higher and secondary technical educational institutions.

Value stream map from the presentation for the seminar “Lean Manufacturing: Tools and Practices”

Why the book is worth reading

- Involuntary comparisons with the theory of lean production are an excellent reason to identify common features and differences of Japanese management and their integration into Russian business;

- Japanese terms fit so well into the entire presented management system that they do not irritate and do not seem foreign;

- Identification of all problems associated with the implementation of Gemba Kaizen in Western markets;

- Psychological and material benefits of kaizen, identified through numerous examples

- Gemba Kaizen as a concept, a management system, and not a separate management tool.

Who is this book for?

For managers at all levels interested in finding methods to maintain and develop the long-term competitiveness of their companies. It will be of interest not only to undergraduate and graduate students involved in management, marketing, quality, logistics and other relevant approaches to doing business, but also to anyone interested in the development of modern economic thought.

Why the book is worth reading

- Goldratt's reasoning method has gained extreme popularity because it allows one to successfully resolve many contradictions: between deadlines and quality, cost and expenses, required productivity and available resources;

- Until recently, information about the basic tools of Goldratt's method of reasoning was presented in a very incomplete and scattered form, and this book is the first systematic, intended for professional use guide.

- With this book, you will be able to determine what needs to change in your organization, how to identify obvious and hidden problems using logic trees, and how to eliminate them.

Who is this book for?

For entrepreneurs and managers at all levels who want to significantly increase business efficiency with the help of breakthrough solutions.

Why the book is worth reading

- Lean Manufacturing VS Lean Procurement;

- Product value stream: how to eliminate non-value-creating steps?

- Net value with zero waste is a reality, not a myth!

- Differences and similarities between the stages of consumption and production against the background of the evolution of the production process;

- The transition from fragmented consumption of individual products to integrated solutions is the ultimate goal of lean consumption.

Who is this book for?

The book is addressed to senior and middle managers, entrepreneurs, specialists of consulting companies, as well as students and teachers of economic universities.

The book provides a step-by-step plan for implementing the 5S system with templates of forms, checklists and other necessary materials. The knowledge gleaned from this book can be successfully used in banks, insurance, consulting and other service companies, government, social and educational institutions.

The advice offered on organizing an effective workplace is so universal that the book can be recommended to a wide range of readers.

The book describes the principles of the revolutionary 5S system - a workplace organization system. The book is aimed at factory employees. But at the same time, it will benefit everyone who wants to make their workplace more efficient (be it a workshop workplace or a bank office, a director’s or accountant’s office).

You will learn how to properly organize your workspace, how to keep it clean and tidy, how to avoid the accumulation of unnecessary things, and as a result make your workplace exemplary.

This audiobook, in a convenient and accessible form, outlines the essence of lean manufacturing methods such as the 5S system or Kanban. With the help of a detailed guide, you can easily monitor unnecessary movement of personnel, identify losses from excess inventory, organize an assault on the workplace, and most importantly, improve the quality of productivity. Quote “Some simple tools are overlooked due to the desire to implement the latest and greatest systems. Make no mistake! The old tools are still in use today and can help organizations simplify production processes and reduce production costs.” Michael Vader What is the audiobook about? About the intricacies of the LIN concept, thanks to which it is possible to reduce production costs, overproduction, long waits for finished products and many other hidden losses. Why an audiobook is worth listening to? Universal edition: suitable both as a tool for lectures in the classroom and for use directly in the production process. 12 key questions have been identified that need to be answered when implementing a LIN strategy. Lean production systems (JIT, 5C, etc.): differences in implementation efficiency. Who is this audiobook for? It will be of interest to anyone interested in quality improvement methods, as well as managers of manufacturing companies and managers of sales departments. Who is the author Michael Vader - President of Lean Plus, Director of the Lean Manufacturing system implementation group, USA. He has more than 25 years of practical experience in teaching, consulting and mentoring in nine countries (USA, India, Indonesia, Russia, etc.). He is a Certified Quality Manager and a Certified Quality Auditor from the American Society for Quality.

On our website you can download the book "Lean Manufacturing Tools. Mini-guide to implementing lean manufacturing techniques" by Vader Michael for free and without registration in fb2, rtf, epub, pdf, txt format, read the book online or buy the book in the online store.

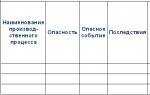

BUSINESS PORTAL “PRODUCTION MANAGEMENT” www. u p p r o . r u 2 0 1 4 LEAN LEAN PRODUCTION 5a algorithms for implementationLEAN 12h eklistov building a roadmap LEAN6s igm PRACTICAL GUIDE TO IMPLEMENTATION Lean: Practical guide to implementation Copyright Portal "Production Management". This Practical Guide or any part thereof may not be distributed without the written permission of the Business Portal "Production Management" or reproduced by any means. It is prohibited to transfer the review to third parties. Organizations that purchased or received this report from the Business Portal "Production Management" are responsible for its non-distribution. All rights reserved. This material was prepared by the Industrial Research Center of the Business Portal "Production Management" for informational purposes only. The information contained herein has been obtained from sources believed to be reliable by Operations Management but should not be construed, directly or indirectly, as investment advice. All opinions and assessments contained in this material reflect the opinions of the authors on the date of publication and are subject to change without notice. Business Portal "Production Management" is not responsible for any loss or damage arising from the use by any third party of the information contained in this material, including published opinions or conclusions, or for consequences caused by incompleteness of the information presented. The information presented in this material was obtained from open sources or provided by companies mentioned in the report. LLC "Production Management Portal" Legal address: 129110, Moscow, 52 Mira Ave., bldg. 3, room III. e-mail: [email protected] for letters: 117418, Moscow, PO Box 109. Website - www.up-pro.ru Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" Lean: Practical guide to implementation Contents Preface I. Preliminary stage of LEAN implementation. Preparation for the start and 6 roadmaps 1 LEAN implementation algorithm according to James Womack 6 2 LEAN implementation algorithm according to Lonnie Wilson 8 3 LEAN implementation algorithm according to Carl Wright 10 4 LEAN implementation algorithm according to Ann Deiterich 12 5 Lean Six Sigma - building a roadmap 15 II. LEAN and Lean Manufacturing. Implementation Guide 22 1 Stage 1: Planning 23 2 Stage 2: Implementation 37 3 Stage 3: Deployment 47 4 Stage 4: Integration 51 5 Stage 5: Improvement 54 III. Checklists for implementing LEAN in production 57 Checklist 1 Building a roadmap for Lean Six Sigma implementation 58 Checklist 2 Assessing production to formulate a LEAN implementation strategy 61 Checklist 3 Basic checklist for assessing LEAN implementation 65 Checklist 4 Visual indicators implementation of 5S 67 Checklist 5 The main sources of losses in equipment operation 68 Checklist 6 Assessing the progress of LEAN implementation 69 Checklist 7 Assessing the involvement of the production team in the implementation of LEAN 79 Checklist 8 LEAN self-assessment and internal audit 82 Checklist 9 Assessing the implementation of LEAN in production (in the workshop) to draw up a work plan 89 Checklist 10 Assessing the effectiveness of working with suppliers as part of the implementation of LEAN 104 Checklist 11 Assessing the level of penetration of LEAN into enterprise management (for top management) 105 Checklist 12 Formation of a LEAN culture at an enterprise 107 Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 4 Lean: A practical guide to implementation Preface The concept of LEAN, or Lean Manufacturing, was introduced to the manufacturing community more than sixty years ago . Over the years, it has been implemented by thousands of businesses around the world with varying degrees of success. It would seem that everything that could be said regarding LEAN has already been said. But with the accumulation of new experience, with the development of production systems, the concept also undergoes certain changes that must be taken into account. Unfortunately, as practice shows, the number of successful examples of implementing Lean Manufacturing is much smaller than those that ended in failure or were not completed. In many ways, the problem is that the implementation was not systematic: managers chose individual areas and tools, guided by their own preferences, the level of their complexity or the most pressing problems of their enterprises, without always carrying out the necessary preparatory work or without thinking through a holistic and detailed implementation program. Having assessed existing Russian-language publications dedicated to LEAN and Lean Manufacturing, we came to the conclusion that the manufacturing community lacks a set of specific steps - an algorithm that should be used in the process of implementing LEAN. In "LEAN. Lean. Practical Implementation Guide" we will close these gaps and give you a simple and clear plan for implementing Lean Manufacturing. On the pages of the Guide we will present several implementation algorithms from leading theorists and practitioners of Lean Manufacturing, without neglecting the modern concept of Lean Six Sigma, using an example of which we will demonstrate how to draw up a roadmap for an implementation project. In addition to implementation algorithms, we have selected checklists for you of different directions and different levels of complexity. They will help you assess your own level and, if necessary, immediately make the necessary adjustments to the implementation program, refine overlooked aspects, preventing problems from moving to the next level. "LEAN. Lean. Practical implementation guide" was prepared on the basis of materials and documents from the world's leading industrial corporations, largest consulting agencies, specialized LEAN institutes, alliances and communities with extensive experience in successful implementation and project support. For you, a group of our experts has carefully revised and adapted the materials taking into account the specifics of implementing Lean Manufacturing in Russia. The concept of LEAN is very broad and can be summarized in one practical guide - or even in an entire book! - impossible. Therefore, we will offer you several algorithms, examining one of them in detail, and touch on the implementation of individual LEAN tools and subsystems, and you can learn about them in more detail in other materials of the Business Portal “Production Management”, Almanacs and Practical Guides. Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 5 Lean: Practical guide to implementation I. Preliminary stage of LEAN implementation. Preparation for the start and road maps During its existence, the LEAN philosophy has confirmed its effectiveness in many companies - from the Toyota Corporation, which made the main contribution to its creation and development, to non-production organizations and institutions. However, despite the popularity and variety of tools, among which each company can find the one most suitable for it, enterprise management and those responsible for implementation argue and doubt where and how best to start. In this section we will look at four algorithms for implementing Lean Manufacturing and an example of forming a roadmap for the modern concept of Lean Six Sigma. 1. Algorithm for implementing LEAN according to James Womack. A major contribution to the promotion of LEAN was made by one of the authors of the bestseller “The Machine That Changed the World,” James Womack. He assigned a key role in the implementation of Lean Manufacturing to the leader, the one who would serve as a conductor of the new philosophy. Implementation algorithm: 1. Select a “change agent,” a knowledgeable and authoritative leader who will take responsibility and guide the implementation process. It is very important to choose a leader who is respected among workers and has a history of implementing successful projects at the enterprise, a specialist whom workers will trust. 2. Organize training. In the second stage, the implementation team needs to undergo basic training in the basics of Lean manufacturing and key tools. 3. Identify or create a crisis. A crisis can serve as a good impetus for the implementation of LEAN, as evidenced by the experience of many companies around the world. But Lean manufacturing is also necessary for successful companies; there is no need to wait for a crisis. There are problems in any, even the most stable enterprise. If necessary, it can be presented as a “cause of the crisis” to encourage employees to eliminate it. 4. Start small, don’t get carried away with strategic issues. It is not necessary to begin the implementation of Lean Manufacturing with a global revision of the entire production process. At the initial stage, you can push workers to eliminate waste wherever they notice it. Later, after the first successful experience, you can move on to more complex tasks, concentrating on the specific goals of the enterprise (order time, production costs, quality). Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 6 Lean: Practical guide to implementation 5. Mapping value streams. Represent the production process as a flow map, breaking it down into individual processes if necessary. This will help you identify bottlenecks, problems and waste. Think about how they can be eliminated and imagine a map of the future flow. 6. Start of work in key areas. Having drawn up a flow map and understood its weak points, without delay, proceed to implementing plans in practice. Information about the progress and results of implementation should be open to all employees. 7. Striving for quick results. Despite the fact that Lean Manufacturing is a long-term strategy, in the initial stages it is better to focus on immediate results: this explains the recommendation to start with simpler tasks. 8. Launch of the kaizen system. Engaging employees in continuous improvement will help you achieve positive results faster. In essence, James Womack proposes moving from the specific to the general: from smaller tasks to reviewing the entire production process, while simultaneously launching a process of continuous improvement and involving more and more departments, workshops and personnel in it. Many consultants and trainers strictly follow these instructions, as a result of which in most enterprises in Russia the implementation of Lean Manufacturing begins with reference areas. The problem is that many find it difficult to move from the level of one site to the entire enterprise, and they stop there. 7 Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" Lean: Practical guide to implementation Stage 1. Planning The first stage - Planning - is the most important in the implementation of Lean Manufacturing, because It is on competent planning that it largely depends on whether the entire program will end in success or failure. This stage includes 18 steps. Step 1.1. Assessing the current state This is the first step in implementing LEAN, without which it is impossible to achieve success. Before you can consistently implement Lean and eliminate waste and bottlenecks, you must understand what needs to be fixed. To implement this step, a special mixed team is created, which includes employees from different departments and different hierarchical levels (necessarily including a representative of senior management), who are well aware of the state of processes in the enterprise. They are the ones who conduct an in-depth analysis of the enterprise regarding 16 management elements: 1. Communication (internal and external). 2. Workplace organization and visual management. 3. Standard operations. 4. Flexibility of operations. 5. Continuous improvements. 6. Error protection (Poka-yoke). 7. Quick changeover (SMED). 8. Total Equipment Maintenance (TPM). 9. Inventory management system. 10. Leveling up production. 11. Engineering. 12. Lean accounting system. 13. Quality management system 14. Work with suppliers and consumers. 15. Maintenance and repair. 16. Performance indicators. To assess the current state of an enterprise, checklists are often used. They allow a more systematic approach to the analysis of processes and, based on pre-thought-out criteria, monitor dynamics even over a long period. Some enterprises develop their own checklists, others prefer to build on ready-made examples. This is a completely typical and normal situation for beginners. Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 23 Lean: Practical guide to implementation As an example, we have prepared for you checklist 2 “Production assessment for the formation LEAN implementation strategy" (p. 61) and recommend using it to identify problem areas of the enterprise. It also includes a comment field where you can describe the problem in more detail. Step 1.2. Diagnostics In the process of implementing LEAN, many companies strive to get visible results as quickly as possible and begin implementing Lean Manufacturing tools, skipping an extremely important step - the formation of a global vision of flows inside and outside the company. Ultimately, they are unable to assess the sources of existing problems and process weaknesses and, therefore, select adequate solutions and tools. The implementation of any tools is effective only if it is carried out in the context of the value chain, which is understood as “all operations carried out in the process of creating a product from the supply of raw materials to sale to the final consumer. Undoubtedly, the results of the internal assessment obtained during the implementation of Step 1.1 indicate the current state of affairs at the enterprise, but they are not enough - it is necessary to understand where exactly the weaknesses of the organization are hidden. A reliable diagnostic tool is value stream mapping, which provides a clear picture of the flow of materials, people and information throughout the enterprise. Improvements are achieved only through the development of a common strategy, since uncoordinated efforts rarely lead to the desired results. It is mapping that makes it possible to analyze the entire technological process, identify operations that do not create value, bottlenecks, serious problems at the organizational level, etc. The team must be able to map the current and future value stream using standard techniques and symbols (Fig. 2). There are several techniques for creating a flow map. As an example, we will present you with one of the algorithms, consisting of six steps. Value Stream Mapping Model So, as the name suggests, this model consists of six steps: 1. Determine the sequence of activities. 2.Calculate the calendar time spent on performing these actions. 3.Calculate the time spent directly performing the action and the time spent waiting. 4.Calculate the time of transition from one action to another. 5.Find and note any loopbacks that occur in the flow. 6.Calculate the average amount of time spent working on the project. To better illustrate this model, let's look at an example. Step 1: Determine the sequence of actions Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 24 Lean: Practical guide to implementation Outside of production Process (not shared) Truck Process (shared) Pushing OK receipts Finished products Information in electronic form Information in another form Data Queue time Reserve stock of materials Application of Kaizen methods Operator Check Supermarket Signal Removal Production Duration of operations Cargo Arrival in batches according to kanban Kanban Sequence Dispatch Inventory quantity Fig. 2. Standard value stream map symbols. For example, let's imagine a process consisting of the following sequence of actions: Submission of a request - Confirmation - Assessment of technical requirements - Approval - Analysis - Development - Review - Implementation planning - Testing - Launch. It is not our task to evaluate this workflow model. Our task is to map it. For greater clarity, operations are located in cells (Fig. 3) Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 25 Lean: A practical guide to implementation III. Checklists for Implementing LEAN in Manufacturing No matter how carefully you draw up a preliminary plan for implementing LEAN, it will inevitably undergo changes along the way - processes, functions, responsibilities, participation and roles of personnel will change as the strategy unfolds. The main thing is to maintain a vision of the final goal, and you can go to it in different ways. The implementation of Lean Manufacturing can take decades, and improvement will last as long as the enterprise itself exists, and it is extremely important to evaluate the result at each stage in order to understand whether you are moving in the right direction, whether the results correspond to plans, whether it is possible to move on to the next step . Self-assessment checklists are a great help in this regard. When considering the LEAN implementation algorithm within the framework of this guide, we recommended the use of certain checklists, carefully selected in order to most fully evaluate the results of individual activities. We have prepared 12 checklists of varying levels of complexity, relating to different tools and different stages, intended for employees of different levels - from implementation teams to the CEO. However, each enterprise is free to choose those that best suit its conditions, parameters and objectives, adjust and supplement them with its own evaluation criteria, or create its own based on them. Checklist 1. Building a Lean Six Sigma implementation roadmap This checklist was prepared to support the implementation of Lean Six Sigma. It helps create a roadmap by looking at the main implementation steps. Each stage is accompanied by a description and listing of key steps. By assessing the completeness and completeness of the implementation of each step on a scale from 1 to 7, you can understand how ready you are for LEAN Six Sigma and how well developed the implementation program is. Checklist 2. Assessing production to formulate a LEAN implementation strategy This checklist is intended to formulate a Lean Manufacturing implementation strategy, assess the degree of enterprise readiness for LEAN implementation and identify problem areas. Enterprises that are faced with a choice of where to start implementation can fill it out to understand what to pay more attention to and in which department and workshop to launch a trial project. The questions included in this checklist are divided into three blocks: Block A is intended for a wide range of enterprises, both those who have implemented LEAN and those who are starting to implement it for the first time. Block B concerns the first results of LEAN implementation and, accordingly, is suitable only for those who already have some implementation experience (both successful and unsuccessful). Beginners can complete this block later. Block C "Future Plans" is suitable for both groups of companies and is intended to highlight the company's production plans. Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 57 Lean: Practical guide to implementation In addition to the standard columns “Yes” and “No”, the checklist includes a column “Comment”, in which the person responsible for filling out the checklist can answer the questions posed in more detail, note statistical data, and point out identified problems, which will allow them to be resolved more quickly. When filling out this column, it is important to note the difference between how things should be and how processes actually are carried out. When assessing, take into account the opinions of several groups of employees: professionals who have worked at the enterprise for more than 10 years, outside specialists with a broad outlook, newcomers to production who can bring a fresh look at problems. In an ideal situation, all potential project team members, future moderators and change agents should fill out such a checklist with extended comments. Checklist 3. Basic checklist for assessing the implementation of LEAN This checklist allows you to assess the current state of the production site in 23 areas of study. Each of them is accompanied by a description of the required (ideal) state. If the condition of the site corresponds to the required one, the person responsible for filling it out puts a “tick” or other symbol in the “Yes” column and awards 1 point. If the answer is negative - 0 points. By carrying out self-audits regularly, you will be able to compare current results with the results of previous audits and thus track progress. Such a checklist is convenient for simultaneous implementation of a project in several workshops or at several enterprises of a group, when there is a need to compare them, despite their peculiarities, according to common criteria. Within the 23 areas of production management, you can add new factors that are key to your production. This checklist allows you to quickly and in accordance with international canons and production management standards assess the effectiveness of your LEAN implementation project. Checklist 4. Visual indicators of 5S implementation Visual inspection of workplaces can be regular or occasional, but even for a basic inspection, during which a controller, department head or consultant checks “by eye” how effective the workplaces are, a systematic approach is required - necessary specific visual indicators, for compliance with which must be checked during the inspection of the workplace. This is what this checklist is intended for, which you can use in its original form or supplement with visual indicators that are appropriate for your workshops. Checklist 5. Main sources of losses in equipment operation Even if the equipment is not idle, but is constantly working at full load, this does not mean that it is working efficiently. The main goal of TPM is to improve equipment efficiency, and therefore eliminate waste that reduces not only the efficiency of machines, but also the efficiency of the operators themselves. This checklist will help you identify the main sources of losses that you should focus on first. You can supplement it with sources of losses specific to your enterprise. Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 58 Lean: A practical guide to implementation Checklist 6. Assessing the progress of LEAN implementation This checklist is designed to track progress in implementing LEAN. To fill it out, you are offered “Questions for expert assessment” on each aspect of LEAN. By answering them, you can understand which stage of implementation you are at. For greater clarity, each stage is accompanied by a list of criteria that will help you accurately determine your own level. For each of the nine aspects of LEAN, you select one stage that is most suitable for you and mark it with a “tick” or other symbol in the “Expert assessment of the current state” column. You can indicate the reasons for choosing this particular stage, identified problems and comments in the “Rationale for expert assessment” column. The changes that have occurred, the progress achieved, and the coverage of areas and departments of the enterprise by the LEAN system are indicated in the column “Progress by block”. The convenience of this checklist lies in highlighting and describing the stages of LEAN implementation, which allows you to standardize the assessment. This checklist is focused not so much on assessing changes in production, but on the level of progress on the Lean Manufacturing implementation project through highlighting its key manifestations. Checklist 7. Assessing the involvement of the production team in the implementation of LEAN A successful implementation project can be stated by the fact of the full and constant involvement of personnel in the work to improve lean production, therefore enterprises need regular assessment of how actively and competently they involve personnel in the process of developing Lean production, How realistic is the participation of staff in decision making? Do employees have the right to decide, the right to agree or only the right to participate? The questions proposed in this checklist relate to nine factors influencing engagement: information policy, organization of projects and planned events, the role of the team of workers and the possibilities of regulation, organization of the project, internal/external support, the impact of LEAN on the work environment, general conditions of personnel policy , powers and resources, employee participation. By answering the questions “yes”, “no” or “partially” and calculating the points, you can assess whether your employee engagement policy is effective or whether you are acting within the framework of the usual directives and calls. This checklist is especially relevant at the stage of implementing LEAN at the reference site and after each cycle of internal and external training. Don’t forget to conduct an employee engagement survey after each revision of plans and after summing up the results of their implementation. Checklist 8. LEAN self-assessment and internal audit Consultants are often invited to evaluate the implementation of LEAN, but the difficulty is that it can be difficult for third-party specialists to understand the specifics of the enterprise in a few days. This unique checklist of 50 questions allows you to independently reveal the main aspects of implementing Lean Manufacturing and evaluate yourself according to the standard methodology, tested in hundreds of enterprises around the world. Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 59 Lean: Practical guide to implementation To simplify filling out each of the fifty questions, a precise explanation is given of what is considered high, medium and low level of compliance with the required state. Thus, even without extensive experience in implementing LEAN, your company’s specialists can conduct an assessment and develop an effective plan for further implementation. It is advisable that the evaluation of the results and completion of the checklist be carried out by specialists who have undergone sufficient training in various Lean manufacturing techniques, have undergone internships at more experienced enterprises, or visited them during educational excursions. This checklist is completed after the first trial runs of Lean Manufacturing have been implemented. Checklist 9. Assessing the implementation of LEAN in production (on the shop floor) to draw up a work plan This checklist offers the opportunity to comprehensively assess the current state of production sites to draw up a work plan based on 95 questions. For each of them, the person responsible for filling it out can make his own assessment, point out identified problems, propose measures to eliminate them, assign a person responsible and preliminary deadlines for completing the task. It is the most detailed and complete checklist for assessing changes occurring in production during the implementation of LEAN, revealing all aspects of project implementation. Thanks to its detail, this checklist will become an indispensable assistant in the process of implementing Lean Manufacturing. The main condition for its effective use is the presence of a highly qualified specialist who will be able to conduct a high-quality assessment of a large number of factors, so it is primarily suitable for internal consultants and project managers for implementing Lean Manufacturing. Checklist 10. Assessing the effectiveness of working with suppliers as part of the implementation of LEAN The development of relationships with suppliers is an important tool within the framework of the work of any enterprise, and when implementing Lean Manufacturing, it is necessary to transfer the system to suppliers, otherwise the potential of “leanness” will not be fully realized. The difficulty is that at this stage a whole series of mandatory conditions, goals and criteria are included that you must meet. This checklist will help you check how ready you are to transfer your system to your suppliers and how much your suppliers are included in your lean system. It is intended primarily for managers of logistics or purchasing departments. When filling out, it is necessary to clearly separate declarative plans for working with suppliers and real everyday facts of mutual integration of interests. Checklist 11. Assessing the level of penetration of LEAN into enterprise management (for top management) The introduction of Lean manufacturing is not limited to improving individual production indicators. Implementation should have the goal of forming a new production culture and influencing all processes and results of the enterprise. The tasks of a manager and a view of the functioning of the enterprise as a whole. Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" 60 Lean: A practical guide to implementation differs from the tasks of the workshop manager or production director, so we have prepared a separate check- a sheet for top managers, which, based on more than forty fairly strict criteria, allows you to track how fully Lean Manufacturing has been implemented. Based on such a checklist, it is possible to develop a corporate system for evaluating Production systems. Checklist 12. Formation of a LEAN culture at an enterprise This checklist helps to assess the level of formation of a LEAN culture at an enterprise according to eight parameters. Each of them, in turn, consists of a number of criteria for which two answer options “Yes” and “No” are offered. In addition, you can state the identified inconsistencies in the “Comment” column and suggest measures to eliminate them. This checklist is most often used at the level of middle (functional) and shop management to assess non-production indicators upon the implementation of Lean Manufacturing. 61 Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" Checklist 3: Basic checklist for assessing the implementation of LEAN (1/2) This checklist allows you to evaluate current state of the production site for 23 study areas. Each of them is accompanied by a description of the required (ideal) state. If the condition of the site corresponds to the required one, the person responsible for filling it out puts a “tick” or other symbol in the “Yes” column and awards 1 point. If the answer is negative - 0 points. By carrying out self-audits regularly, you will be able to compare current results with the results of previous audits and thus track progress. Such a checklist is convenient for simultaneous implementation of a project in several workshops or at several enterprises of a group, when there is a need to compare them, despite their peculiarities, according to common criteria. Within the 23 areas of production management, you can add new factors that are key to your production. This checklist allows you to quickly and in accordance with international canons and production management standards assess the effectiveness of your LEAN implementation project. 0-7 points - low level 8-15 points - average level 16-23 points - high level Enterprise / Shop / Department: Points: Completed: Past result: No. Area of production management Required state 1 Standardization of processes The production process is documented and constantly improved. Compliance with standards is of paramount importance 2 Flow production The flow of single products is organized, buffer stocks between technological operations are minimal 3 Personnel involvement The competencies of workers and the opportunity to participate in the decision-making process on important issues are expanding 4 Safe processes For each process, the risk coefficient for the occurrence of manufacturing defects is calculated, as well as the consequences of such defects for subsequent operations 5 Continuous improvement The company has NMP, kaizen or other methods of continuous improvement of processes, they are given serious support from management 6 Flexibility Production is able to adapt to orders with different volumes and lead times, to expand or change the product range 7 Monitoring Modern technical means are used to prepare reports and collect production indicators regarding the quality of equipment, customer satisfaction, assessing the performance of suppliers, etc. 8 Transparency Work is underway to increase the transparency of processes; information about the status of the order and the degree of achievement of the goal is posted at each workplace Yes (= 1 point) Date: No (= 0 points) Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" Checklist 3: Basic checklist for assessing the implementation of LEAN (2/2) No. Area of production management Required state 9 Systematic implementation Each stage of implementation is supported by directives and resolutions of management, consistent with the general strategy; adherence to the general strategy is mandatory 10 Pull production A pull system is organized, production volume is coordinated with demand, there are no warehouse stocks (with the exception of cases of forecasting increased demand for certain products) 11 Flow of single units products The product in the processing process passes directly from one stage to the next, both on the conveyor and in the production cell 12 Kanban To implement the just-in-time principle, the kanban system is used, replenishment of materials at the workplace occurs strictly as needed 13 Qualifications All employees and managers have received appropriate training 14 Poka-yoke A system is in place to prevent errors using simple technical innovations 15 Material flow Material flow is reorganized to create a pull production system 16 Flow manufacturing Production processes are divided into work operations with a given cycle The workshop space is re-equipped according to the sequence of operations 17 Separation of work Separation of productive work from activities not directly aimed at the production process 18 Visual management To visualize the processes occurring in the enterprise, graphs, tables, inscriptions and indicators are used to demonstrate the difference between the current state and the planned one, that is, they serve as a guide for the improvement process and motivate employees 19 Relations with suppliers In connection with the changes that have occurred, contracts, ordering procedures and methods of communication with suppliers have been revised, work is underway to extend LEAN to suppliers 20 Customer focus Work is underway to improve relations with clients: the ability to promptly inform about the client’s preferences, dissatisfaction and wishes 21 Reducing transport routes The routes and methods for transporting materials and products have been revised (it is possible to involve logistics operators) 22 Optimization of internal movements The routes for movement of workers and transportation of materials and products have been revised (redevelopment of workshop space) 23 Standardization of time for performing operations The method of planning and evaluating production processes is used based on measuring the duration of work Yes (= 1 point) Demo version. Full version: http://www.up-pro.ru/shop/lean.html Copy of the company "________________________________ __" No (= 0 points) 15,000 rub. System of continuous improvements: the experience of the Bundeswehr. Practical guide. Order and thoroughness are the main characteristics of the German army! And this order is reflected in this Practical Guide in everything: in forms, instructions, algorithms for evaluating proposals, resolving controversial issues, principles of remuneration and assessing the effect of implementing proposals. This manual is a charter, just not for service, but a charter for a continuous improvement system (CIP), which, like a real charter, leaves no room for doubt or double interpretation, which has been worked out for years and is easy to study and implement, describes all aspects and solutions necessary for the quality of the process. Its main advantage and distinctive feature is that this is not a book or an article, not general recommendations on how to live better, not a description of philosophy - it is a rigid standard, a set of rules, instructions and algorithms that ensures 100% efficiency and quality of the NPU process. .... Several employees submitted similar proposals... The proposal includes a development that may be subject to protection by copyright and patent laws... The submitted idea is within the immediate responsibilities of the employee... What to do in these cases? ... What to do if the proposal contains the grain of rationalization, but is presented in a general form and lacks specifics? What if it approaches partial implementation? What are the grounds for refusing to implement the proposal? ... The implementation of the system begins, and the questions keep multiplying, discouraging any desire to continue and bringing to mind the frequent thought “kaizen/NPU/innovation is not suitable for us,” which is expressed with enviable consistency by enterprises of various profiles. Understanding the difficulties that domestic enterprises face, the Business Portal “Production Management” has prepared for you a practical guide to creating a system of continuous improvements, using the Continuous Improvement Program in the Bundeswehr as an example. What will such a system bring to you? Firstly, it will significantly simplify the processing of improvement proposals and prevent you from getting confused in a difficult situation. Despite the fact that the Program relates to military structures, the principles set out in it for organizing a system of continuous improvements are suitable for enterprises in any industry. The presentation of these principles in the format of the charter provides a precise and detailed description of the NPU system in German, with attention to every detail - from the division of powers to the determination of the amount of the bonus to the author of the idea. In addition, the Charter contains clear instructions in case of controversial situations, which are not uncommon in the process of work. Secondly, it will help distribute responsibilities between employees at different levels. By transferring the functions of the Bundeswehr departments to the hierarchical structure of your enterprise, you will be able to more easily navigate your areas of responsibility. And thirdly, we should not forget about such an important - and perhaps a key - factor in the success of the NPU system as the degree of employee motivation. If you do not have a system for evaluating improvement proposals, if in controversial situations you rely on the situation, personal experience or someone else’s opinion, and not on clearly defined standards, do not be surprised if you are accused of subjectivity or misunderstanding. And a person who believes that he was unfairly rejected is unlikely to show zeal in the future. “The uniqueness of this manual is the presence of a large number of provisions, instructions and forms (more than half of the handbook). The second half of the guide consists of practical algorithms for organizing the rationalization process itself. You can print out many forms virtually unchanged and immediately begin using them in production. There are no analogues to this manual on the subject of Lean Manufacturing in Russian.” Stanislav Zinchenko, Director of the Center for Industrial Research of the Business Portal "Production Management" Buy Demo version of VVVTOOQNQT 5S: Practical implementation guide 15,000 rub. How to determine an enterprise's readiness for 5S? Where to start implementation? How can a line manager, an external auditor, or the employee himself assess the state of the workplace? The answers are in the new unique product “5S. Practical implementation guide." Clear and accessible algorithms, 15 checklists of varying difficulty levels, examples, photos and much more! This Practical Guide is a detailed step-by-step algorithm for preparing and implementing activities as part of the implementation of the 5S system at an enterprise: from developing a plan and drawing up a project map to evaluating the results obtained. For each stage of 5S (sorting, self-organization, systematic cleaning, standardization and improvement), goals and implementation time are determined, a list of necessary materials, recommendations for implementation, clarifying comments and, of course, criteria for assessing success are proposed, only if they are met can one proceed to the next stage. Its strength is its maximum focus on practical use. Dozens of books have been written about the theoretical component of the 5S concept; for this reason, we based the Practical Guide on the real experience of industrial enterprises, non-production departments, consulting agencies and the principle of “Print and use” rather than “Read and think.” Therefore, we can safely say that there are no analogues in the Russian-speaking environment. Of particular interest to practitioners is the block “Checklists for the implementation of 5S”, without which it is impossible to assess the achieved level. Here we have tried to cover as broadly as possible the requirements of enterprises of different profiles and different levels of training. The Practical Guide provides checklists for individual self-assessment and for team work, for an assessment that takes only one minute, and for an in-depth study of the process of implementing the 5S system, for workplaces and collective premises, for ordinary employees, auditors, line managers and department heads. In a separate block, we have presented checklists for you that will help you effectively organize and check the work of offices and non-production departments. Each checklist is universal and maximally adapted to the needs of a wide range of enterprises. Naturally, each enterprise has its own unique characteristics and requirements, but even if these differences are fundamental, you can easily adjust the presented checklists to suit your specifics, job hierarchy, requirements for organizing workplaces or holding special events. Why is 5S useful? Practical guide to implementation": 1. Practical guide will help you correctly start and implement the 5S implementation project at all its stages. 2. The practical guide will provide the 5S project manager at your enterprise with all the information he needs and will help him draw up a work plan. 3. Practical guidance will save you from the need to invent and develop dozens of new documents for the 5S project. 4. Practical guidance, thanks to more than a dozen checklists, will bring your 5S implementation project to the level of international standards. 5. Practical guidance and its correct application will ensure the implementation of 5S at all levels of the enterprise and in all departments. Buy Demo version Full version: http://www.up-pro.ru/shop/lean.html Copy of the company Demo version. "_________________________________"

The lean manufacturing (LP) methodology has been used to optimize business processes in Russia for more than ten years. However, despite the fact that many organizations claim to use BP tools, few companies in Russia are truly lean

Ivan AlekseevichWatchman,

Postgraduate student, Department of Aircraft and Helicopter Engineering, Federal State Budgetary Educational Institution of Higher Education «

Novosibirsk State Technical University"

annotation . The subject of this article is a description of algorithms for applying the concept of “Lean Manufacturing” by Taiichi Ono, James Womack, Michael Weider, Jeffrey Liker, Shigeo Sing, Dennis Hobbs. All presented algorithms are divided into steps and a brief description of each step is given. In conclusion, the article makes an attempt to combine the presented algorithms and the author’s experience in applying the concept. As a result, our own algorithm is described.

Abstract The subject of this article is description of the algorithms of "Lean Production" Taich Ohno, James Womack, Michael Vader, Jeffrey Liker, Shigeo Singo, and Dennis Hobbs. All presented algorithms are divided into the steps and description of each step are briefed. In conclusion, the article is an attempt to combine the algorithms presented and experience of the author on the application of the concept. As a result, it described its own algorithm.

Keywords : lean manufacturing, Lean production, business process optimization, operational efficiency

Keywords : Lean Production, optimization of business processes, operational effectiveness.

Introduction

The lean manufacturing (LP) methodology has been used in Japan for more than 60 years. In America, the term Lean production was introduced by John Krafcik in 1990. On the territory of Russia, the Gorky Automobile Plant (GAZ) is considered a pioneer in the field of power supply. The first Japanese consultants arrived in Russia in 2002, and already in March 2003 GAZ began optimizing the existing production system. Thus, for 13 years now, Russian enterprises have been using the BP concept to optimize business processes.

Consulting centers and consultants in the field of BP offer their algorithms for using BP. This article will give a brief overview of existing ones and propose our own model for using this concept.

Despite the fact that many companies claim to use BP tools, not many companies in Russia remain truly lean. It is quite difficult to identify the reasons for the current situation. Some consultants argue that there is no consistency at all stages of implementation. Someone says that BP is a philosophy and many years must pass for its adoption. There is also a strong opinion that all efforts to introduce BP are frustrated by the strong centralization of power at the enterprise, or by the Russian mentality of workers. In fact, it is not entirely correct to give such an assessment. Because no two BP projects are the same. Thus, it can be argued that none of the algorithms proposed to date is universal for enterprises of the Russian Federation.

Taiichi Ohno's algorithm

Taiichi Ohno is considered the developer of the Toyota Production System (TPS), on the basis of which the concept of power supply was formulated. Taiichi Ono himself does not offer a clearly formulated algorithm, but describes the steps he took in the book “Toyota Production System. Moving away from mass production."

Step 1: Implement the production flow concept. Combining various machines into a single technological chain and building the flow of a single product.

Step 2. After building the production flow, previously hidden losses are revealed. To eliminate production losses, it is necessary to optimize the operation of the line. Optimization includes the use of a pull system, the use of a Kanban system, standard operation sheets, leveling production or reducing fluctuations in the flow of products on a production line, rapid changeover of equipment, and visualization.

Step 3. Installation of an autonomous machine control system - autonomation. Automation prevents defects or overproduction during the production process by stopping the machine, line or conveyor. Also at this stage it is necessary to use the Andon system, which notifies the employee of the need to intervene in the operation of the machine.

Step 4. Improvement of technology. To do this, it is necessary to use not the latest, but reliable and proven technology. Studied and tested technology is implemented faster and produces more effective results.

Step 5. Development of company employees and development of partners. Employee development involves developing leaders who know their business well, adhere to the principles and philosophy of the company, and can teach this to others. Improvement of partners is achieved by setting more complex tasks, as well as helping partners solve problems.

James Womack's algorithm

Today, the most popular algorithm is the algorithm of the American researcher, one of the authors of the term Lean Production, James Womack.

Step 1. Choose a leader who enjoys authority in the team. Form an authoritative BP implementation team. Members of this team must have experience in managing projects and must be trusted by company employees. The main goal of the team is to “ignite” the company’s staff with the idea of frugality.

Step 2. The BP implementation team needs to be trained in the principles and use of BP tools.

Step 3. Identify or artificially create a crisis in the company. There are always problems, in any enterprise. It is necessary to choose the most acute one, and then encourage the team to eliminate it.

Step 4. It is necessary to begin the implementation of BP gradually, pushing employees to eliminate losses wherever they notice them. Then you need to solve more complex problems: improve consumer properties, reduce system response time, reduce production costs.

Step 5. Schematically depict the production process in the form of a value stream map. If the process is complex, it can be broken down into separate subprocesses. The map will help identify bottlenecks and existing losses in the process.

Step 6. Implement an action plan based on the results of the compiled flow map and future state model as soon as possible. The action plan and the results of its implementation must be available to all employees.

Step 7. It is necessary to focus on short-term results, solving simple problems at the initial stages.

Step 8. Involve employees in the process of continuous improvement using Kaizen.

Michael Vader's algorithm

Michael Vader is the president of an American consulting company, the author of three books about BP and one of the first foreign consultants in Russia.

Step 1. Assessing the current state of the enterprise. To do this, it is necessary to determine how poorly or well organized the processes in the enterprise are and how effective these processes are. PSU compliance certification is recommended as a tool for assessing the current state. Based on the certification performed, the most ineffective process and the main types of losses of the selected process are selected.

Step 2. Implementation of the 5S system in the process selected in step 1. When organizing a workplace, process losses become more obvious: excess work in progress and unnecessary additional operations.

Step 3: Develop a value stream map. This step will help determine the optimal points where it is worth using Kanban and the Just In Time method. There is also the possibility of detecting hidden losses, to eliminate which it may be necessary to use built-in error protection, quick changeover or zoning using visual inspection.

Step 4: Using a continuous improvement philosophy, go back to Step 1 and select the most inefficient process in the new production system.

Jeffrey Liker's algorithm

Jeffrey Liker is the author of eight books on LP, winner of eleven awards for excellence in LP research, professor of industrial and operations engineering at the University of Michigan, and president of the consulting company Liker Lean Advisors.

Step 1: Define your company's purpose and act on it. First you need to develop your own company philosophy. Based on the philosophy, develop a long-term development strategy. Next, management, managers, foremen and all employees must make the company's philosophy their way of life. Managers must demonstrate by example their commitment to the philosophy on a daily basis. The chosen goal must be constant at all stages of the company’s life, regardless of external and internal circumstances.

Step 2: Start cutting your losses. To do this, you must first understand BP concepts, implementation strategies, and effective application methods. Then come up with an implementation plan that includes continuous cost reduction.

A. Start improving not individual processes, but create a value stream map of the entire company.

B. Ensuring a basic level of stability of the company's processes. Stability will help eliminate unsystematic actions and see the actual state of processes in the company.

C. Finding and eliminating major losses. To eliminate losses, TPS tools are used: standard work, 5S, TPM, SMED, variability reduction.

Step 3: Create a coherent process flow. To do this, you need to: create a flow of single products; constantly monitor overproduction; align the work cycle time of the site and the takt time of product manufacturing; build a pull system that allows you to determine when the process of transferring material from site to site occurs; organize the process according to the First-In-First-Out (FIFO) principle.

Step 4. Alignment. Evenly distribute the amount of work and the combination of types of work.

Step 5. Create a culture of improving product quality. To do this, it is necessary to make stopping production to solve problems part of the company culture. We are talking not only about employees, but also about “smart machines” - Autonomation. At the same time, it is necessary to constantly strive to reduce the downtime of production lines. The use of the “poka-yoka” method (error protection) also helps the operator prevent errors.

Shigeo Sing's algorithm

Shigeo Sing is considered one of the creators of the Toyota Production System, as he worked closely with the company and with Tahiti Ono. He is the author of the quick changeover system - SMED, and has written more than 20 books on management. He has a large number of awards in the field of production optimization and operational efficiency and even an award called the “Nobel Prize in Manufacturing” was named in his honor.

The Shigeo Sing algorithm (Sing model) consists of four stages and is represented as a house.

Step 1. The basis of the “House” is the foundation. For a strong foundation, it is necessary to: ensure safe working conditions for employees, build and constantly maintain a system for developing employee competence, and continuously expand the rights and capabilities of each employee.

Step 2. The first floor of the “House” consists of a process of continuous improvements. To build an improvement process it is necessary:

A. Achieve process stability and standardize these processes.

B. Make direct observations. When making decisions, you need to trust the facts and the data received.

C. Create a value stream focus and pull process.

D. Ensure quality system improvement.

E. Identify and eliminate waste, integrate the improvement process into daily work, simplify and visualize existing information.

Step 3. Second floor - leveling process. To align the process, it is necessary to think systematically and ensure consistency of purpose. Focus on the long term, align the system and strategy, standardize daily processes.

Step 4. Roof of the “house” - results. The main result in the implementation of BP is the creation of value for consumers. To do this, Singa recommends: measuring only what matters, aligning production rhythm with productivity, and identifying cause-and-effect relationships.

Dennis Hobbs Algorithm

Dennis Hobbs is a Certified Production Management and Inventory Accounting Specialist. An author of numerous articles and a popular lecturer, Hobbs is an active member of APICS (Association for Operations Management).

Step 1. Formulate the goals of the project and targets for future production. Determine the composition of teams and train participants. Make an action plan. Begin collecting process and product information needed to design a lean line.

Step 2: Determine process performance taking into account variability, reprocessing and waste. Identify product families based on process similarities. Identify Kanban components and document component consumption and replenishment points. Set pull chains and replenishment times.

Step 3. Achieve consensus and steering committee approval of decisions on products, output, and available labor time on the lean line. Complete documentation of the sequence of events, process durations, quality requirements, and required resources for the designed line.

Step 4. Develop a paper layout of the lean line based on the calculated amount of resources. Locate the Kanbans that trigger the previous process. Develop a detailed implementation plan for the Kanban system. Determine operator training requirements. Develop a schedule for technological and organizational transformations of the line.

Step 5. Check the line balance and the ability of the operators to switch. Make sure that tasks are distributed correctly among work stations and that the layout is ergonomic. Develop a plan to gradually reduce work-in-process inventories. Ensure the implementation of a mechanism for continuous process improvement.

Step 6. Identify deviations and develop correction strategies. Review assignment of responsibilities and modify policies and procedures to improve management. Ensure that all systems necessary to manage the lean line and Kanban system are in place.

Conclusion

There is no universal algorithm for implementing a BP program at an enterprise and, probably, there never will be due to the lack of two identical BP projects, as mentioned earlier. But it is definitely possible to develop recommendations for those companies that are just at the stage of transforming their production system. It should be noted that when choosing any algorithm, it is necessary to draw up a detailed plan for its implementation, indicating specific responsibilities and deadlines for the implementation of plan items.

Step 1. Respect for employees. A leader should help and teach, not control and command. It is important for employees not only to feel respect, but also to see it. A clear confirmation of this is the results of the “Hawthorne Experiment”. To achieve this, it is necessary to improve occupational safety and provide employees with opportunities for development. An important part of respect is having opportunities for employees to speak up and realize their potential. To do this, it is necessary to build a system of problem solving boards and a system for submitting and implementing rationalization (Kaizen) proposals.

Step 2. Formation of mission, goals, strategies and objectives. After creating a single collective team and answering the question “Who?”, you can use the team to answer the question “What?”. The mission is necessary to determine the direction of the company's development. A goal is needed to quantify the company’s achievement of its stated mission. Strategies are necessary to formulate ways to achieve a goal. Management sets tasks for departments and functions to achieve the overall goal of the company. In order for the mission, goals, strategies and objectives not to remain just slogans, it is necessary to start monitoring the achievement of the goals on a daily, weekly, monthly and annual basis. Such monitoring should become habitual for all levels and all employees of the company. A meeting system with a clear description of the topics of each level of the meeting and the composition of participants can help with this.

Step 3. Formation of a team of BP experts. It is necessary to select people who will undergo BP training and then act as experts in implementing the next steps. The team should also include improvement coordinators - employees responsible for reporting the company’s improvement activities. In this case, BP experts should be current employees of the company, and coordinators should be a separate function.

Step 4. Formation of a lean flow.

A. Build a value stream for one product. It is necessary to minimize the batch being produced, and after processing is completed, immediately transfer it to the next stage.

B. Build a pull system. To do this, it is necessary that the section, after completing the processing of a batch, does not transfer it until and does not proceed to the next batch until the previous section has processed the previously issued batch.

C. Create a Kanban system. It will allow you to visually determine the time of transfer of the batch to the next stage and the start time of production of a new batch.

D. Standardize all operations to eliminate variability and smooth production. To do this, you can use standard operation sheets and the 5S system. A working group of site employees should standardize operations.

E. Based on demand statistics, determine the optimal quantity of goods in stock to reduce fluctuations in product flow.

After building the production flow, previously hidden losses are revealed.

Step 5: Improve operational efficiency. It is necessary to eliminate identified losses, as well as reduce costs, by optimizing the established value stream. To optimize it, you need to select a suitable standard BP tool

· Effective organization of the “5S” workspace. The tool allows you to reduce the number of operations and/or reduce the total time to complete them.

· Standard work "SW". It is necessary to find best practice and formalize it as a standard. After everyone involved in the process has learned to accurately implement the standard, it is necessary to review it and find a new best practice. Standard work is impossible without performing step No. 2.

· Value Stream Map “VSM”. Helps analyze the selected value creation cycle, identify losses and identify bottlenecks.

· Poka-yoka error protection. In case of systematic deviations from the standard, it is necessary to revise the procedures performed in such a way as to minimize the likelihood of an error or completely eliminate it.

· Fast changeover "SMED". Reduces production losses that occur during equipment changeover. At the initial stage, it is enough to divide all changeover operations into internal and external ones.

· General effective care of TPM equipment. Helps reduce unexpected losses and reduce the cost of equipment repairs.

Step 6. Continuous quality improvement. It is necessary to make quality indicators one of the main ones, along with the financial indicators of the company. This step will help focus all employees on fostering a culture of continuous quality improvement. An increased focus on quality will not only reduce the number of employee errors, but will also help them think about autonomy. Automation (or jidoka) implies the automation of processes with elements of intelligence.

Step 7. Improvement. Using the principles of continuous improvement and continuous growth, it is necessary to create a plan for implementing improvements for the changed production system, returning to the first step. At the same time, at each step it is necessary to ask the questions “What else can be simplified?” and “What else can you visualize?”

With good tools, a company can achieve great results. But as soon as you use the tool incorrectly, or use it formally, the tool begins to bring only harm to the company instead of benefit.

List of used literature

1. Womack D., Jones D. Lean production. How to get rid of losses and achieve prosperity for your company. - M.: Alpina Business Books, 2009. – 473 p.

2. Vader M. Lean manufacturing tools. Mini-guide to implementing lean manufacturing techniques. - M.: Alpina Publisher, 2015. – 151 p.

3. Liker D. DAO Toyota. 14 management principles of the world's leading company. - M.: Alpina Business Books, 2009. – 402 p.

4. Mann D. Lean management: Lean production. //Standards and quality. - 2009. – 208 p.

5. Ono T. Toyota Production System. Moving away from mass production. –M.: ICSI. – 2005. – 192 p.

6. Shingo S. Study of the Toyota production system from the point of view of production organization. - M: ICSI, 2006. – 312 p.

7. Storozh I., Ryakovsky S., Kurlaev N. Analysis of the application of the lean production concept: Russian and Western companies // Scientific Review. – 2016. – No. 6, pp. 202-206.

8. Hobbs D. Implementation of lean manufacturing: a practical guide to business optimization. - Minsk: Grevtsov Publisher, 2007. – 352 p.

9. Yagofarov A. How to choose a strategy for implementing the Lean Production program // Methods of quality management. – 2013. – No. 12, pp. 4-9.

References

1. Vumek D. P., Dzhons D. T. Lean production. How to get rid of waste and ensure the prosperity of your company. Moscow, 2009. 473 p.

2. Veyder M. The Tools of lean manufacturing. Mini-guide to the implementation of lean manufacturing techniques. Moscow, 2015. 151 p.

3. Layker D. DAO Toyota. 14 principles of the leading companies in the world of management. Moscow, 2009. 402 p.

4. Mann D. Lean Management: Lean Manufacturing. Moscow, 2009. - 208 p.

5. Ono T. Toyota Production System. Leaving from mass production. Moscow, 2005. - 192 p.

6. Shingo S. Toyota production system study from the organization of production. Moscow, 2006. - 312 p.

7. Storozh I. Ryakovsky S. Kurlaev Analysis of application of the lean production concept: Russian and foreign companies. // Scientific Review, 2016, No. 6, pp 202-206.

8. Hobbs D. Implementation of lean manufacturing: a practical guide to business optimization. Minsk, 2007. - 352 p.

9. Yagofarov A. How to choose a strategy for the implementation of "Lean Manufacturing" program // Methods of Quality Management, 2013, No. 12, pp 4-9.